GRP tank lining Lining Systems GRP ESI Enviropro

GRP Lining Secondary Containment Liquid Applied Membranes GRP

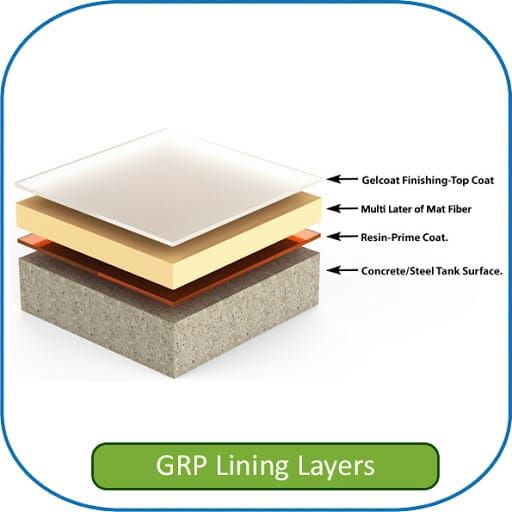

Top-down view of a primary containment vessel WWW.STRANDEK.CO.UK Fibreglass (GRP) Linings Example fibreglass lining for a variety of substrates The image below is of a fibreglass lining or coating. It comprises multiple layers on top of a substrate, typically made from wood, concrete or certain metals. These layers are often built up from (1) a.

GRP Lining Services Liquid Waterproofing Jones and Woolman

Fibreglass (GRP) linings and coatings are incredibly versatile and effective means of waterproofing and protecting a variety of surfaces and structures. They offer exceptional durability and protection from mechanical, chemical and biological stress. Strandek® has specialised in GRP lining and coating technology since 1976 and are considered.

GRP Tank Lamination Suppliers & Contractors in UAE GRP lining Service

GRP Lining is a process of applying a permanent layer and lasts a lifetime. GRP lined tanks are suitable for potable water storage as we use the same materials used to manufacture water tanks. Fiberglass coated or laminated or waterproof tanks will last the life of most equipment without leaks or corrosion failures.

Commercial GRP Lining Liquid Applied Membranes GRP Lining LAM

2. Purpose & Scope. This method statement is for the purpose of installing or applying Glass Reinforced Plastic known throughout this document as GRP. The method statement for the application of grp lining will particularly cover water tanks, sewage pipes, and manholes together with stormwater drainage systems and underground water tanks.

GRP Lining System Tank Lining Liquid Applied Membranes

1 = base substrate (concrete or equivalent), 2 = primer (optional), 3 = fibreglass laminate and 4 = grey resin topcoat. In the following section, we will assume the underlying pond base structure has been built and will detail how to construct a fibreglass (GRP) lining. If you would like to watch a video version, please see below: This section.

GRP Lining Company in Dubai UAE Salman Syed Technical Services

GRP lining is the process of using Glass Reinforced Plastic (GRP), also known as Fiberglass, to line the interior of a structure or container. This lining is used to protect against corrosion and to provide a smooth, durable surface that is easy to clean and maintain. There are several different types of GRP lining, including:

Water Storage Tank GRP Lining Tank Lining Sui Generis

A method statement for GRP (Glass Reinforced Plastic) lining works outlines the procedures and steps involved in the installation of GRP linings. The following is a general outline of the procedure for installing GRP linings: Surface Preparation: The first step in the installation of GRP linings is to prepare the surface.

GRP Lining Refurbishment. Flexible polyurethane tank lining

Note: the term "glass fibre lining" also refers to "glass fibre coating" throughout. Likewise, glass fibre is also commonly known as GRP (glass reinforced plastic/polyester) and fibreglass. WHAT SUBSTRATES ARE SUITABLE FOR FIBREGLASS? GRP linings are incredibly versatile and durable.

Industrial Roof Gutter Lining GRP Lining Sui Generis

Fibreglass (GRP) linings and coatings provide a significant benefit to concrete surfaces and structures. They provide waterproofing, chemical resistance, abrasion and erosion resistance. They also provide protection from physical impact and stress, making them suited to a huge range of applications.

Industrial Linings, Tank Lining, GRP Lining Liquid Applied Membranes

Introduction Large diameter pipelines and culverts represent the backbone of any city's utility network for the collection and disposal of sewerage and effective drainage of storm-water.

Fiberglass GRP Lining Al Harth Fibre Glass

Wholesale China Products. Customizable Logo/Size/Color.

GRP LINING SYSTEM

Title. Method Statement for Installation of GRP Lining to Water Tank at Basement. 2. Purpose. The purpose of this method statement is to describe the measures and system, a procedure that will be adopted for GRP lining installation to the basement water tank. This method statement has been prepared based on the method statement from the.

GRP tank lining Lining Systems GRP ESI Enviropro

GRP lining is considered to be most advantageous for reliable waterproofing solutions. Its significant attributes help the material to be easily molded to any type of shapes, sizes and designs. As it is manufactured in range of colors and finishes, it holds great commercial viability in market. GRP Lining services in Dubai makes the best use of.

Industrial Roof Gutter Lining GRP Lining Sui Generis

GRP Lining Meaning: Glass reinforced plastic GRP is molded plastic reinforced with lengths of glass fibre. Injected molded GRP has very short fibre length up to 3 mm whereas composite laminating and DMC and SMC molding have long or continuous lengths of glass fibre reinforcement.

grpbundlining Liquid Applied Membranes GRP Lining LAM

GRP Lining is a permanent layer coating process for Concrete Tanks to prevent leakage and water absorption, GRP Lining for Underground Concrete water tanks prevents algae and fungal growth. GRP Lining is permanent layer coating process, and will last for a lifetime. GRP lined tanks are suitable for storage of potable water as we are using the.

Commercial GRP Lining Liquid Applied Membranes GRP Lining LAM

GRP Lining (also known as glass-reinforced plastic lining or fibreglass lining) amalgamates the robustness of glass with the endurance and pliability of plastic. It is created by forming a mat of glass strands and subsequently enveloping it with a polymer.